WIZ OF A PERFORMANCE BY LANDIA'S MIXERS IN KANSAS

Over a decade on from an installation at a major wastewater treatment plant in Kansas, leading pump and mixer manufacturer Landia has once again demonstrated the longevity of its equipment by helping its customer get the original kit back into optimum operation.

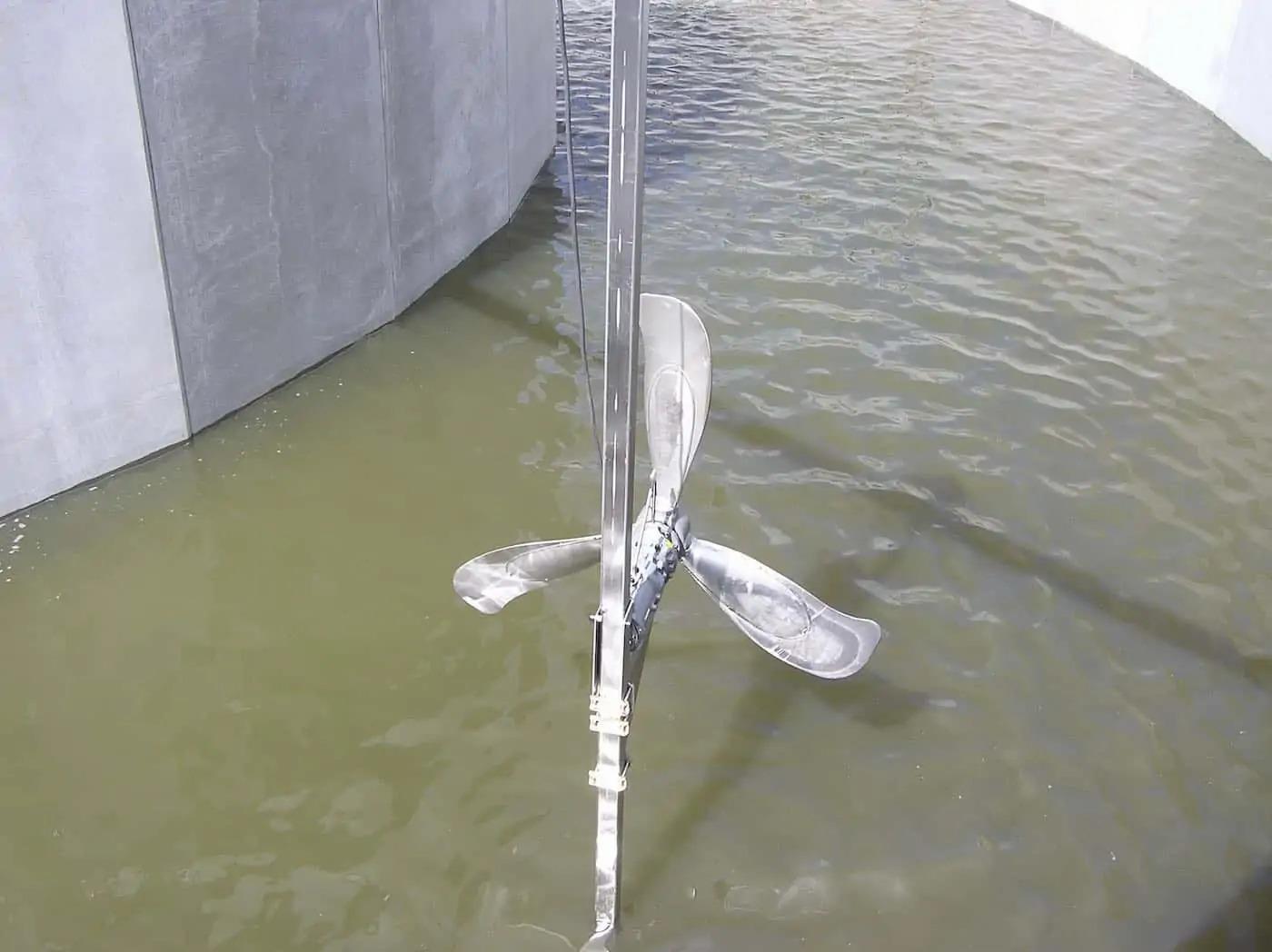

Back in 2004 Landia installed 10 of its model POP-I 4.9 HP 180 rpm submersible mixers in the anoxic basins at a WWTP in Kansas State, which together with its sister treatment plant has the capacity to treat 28 million gallons of wastewater daily.

Although Landia offered (as standard) full operation and maintenance assistance by its skilled service technicians, the WWTP opted instead to use a local motor repair shop. This only came to light just recently when Landia and other manufacturers received an invitation to bid on the replacement of three mixers.

Landia immediately contacted the plant manager, whereupon it was discovered that the only reason the mixers were not achieving optimum results was because inferior quality, non-manufacturer parts had been used, together with incorrect maintenance procedures.

Kenneth E. Jacobs, Jr., Landia Technical Services explains: “Apart from routine maintenance it is such a rarity to receive a call about our mixers not performing at their best. We pride ourselves on a second-to-none back-up service for our customers, so I quickly arranged a meeting at the plant to see how we could help”.

He added: “It turned out that the staff at the treatment plant had actually been very happy with the Landia equipment, but had a lack of understanding on how to maintain it”.

Without further ado, plant personnel were given on-site training by Kenneth, who also offered to take back two of the mixers that were currently out of operation and restore them to proper working condition in order to save the plant from spending money on the purchase of brand new mixers.

The two out-of-action mixers arrived in a crate, completely disassembled, but Kenneth soon put the mixers back together using all the original parts, replacing only worn items as required, returning two good-as-new mixers to site. The mixers’ stainless steel propellers, even after 10 years of operation, were still in perfect operating condition.

As a result, even though the official bids had already been submitted, Landia’s efforts inspired the plant manager to cancel – and fully reinstate the Landia mixers. In future, Landia will now be refurbishing all of the mixers as and when required.

Kenneth E. Jacobs added: “At Landia, we are always prepared to go the extra mile to help our customers keep their plant maintenance back on track. As soon as we knew the treatment plant operators in Kansas needed some assistance with the mixers, we wanted to get in there as soon as we possibly could and provide a solution”.

This latest example of Landia propellers still being in perfect working order after many years of service follows a recent similar long-service success story in Maryland, where 12 Landia mixers had their motors replaced after almost two decades of operation – yet the original stainless steel propellers were still intact.

Landia is now offering an unprecedented 20-year warranty on its stainless steel propellers.