Dry-installed chopper pumps for biogas

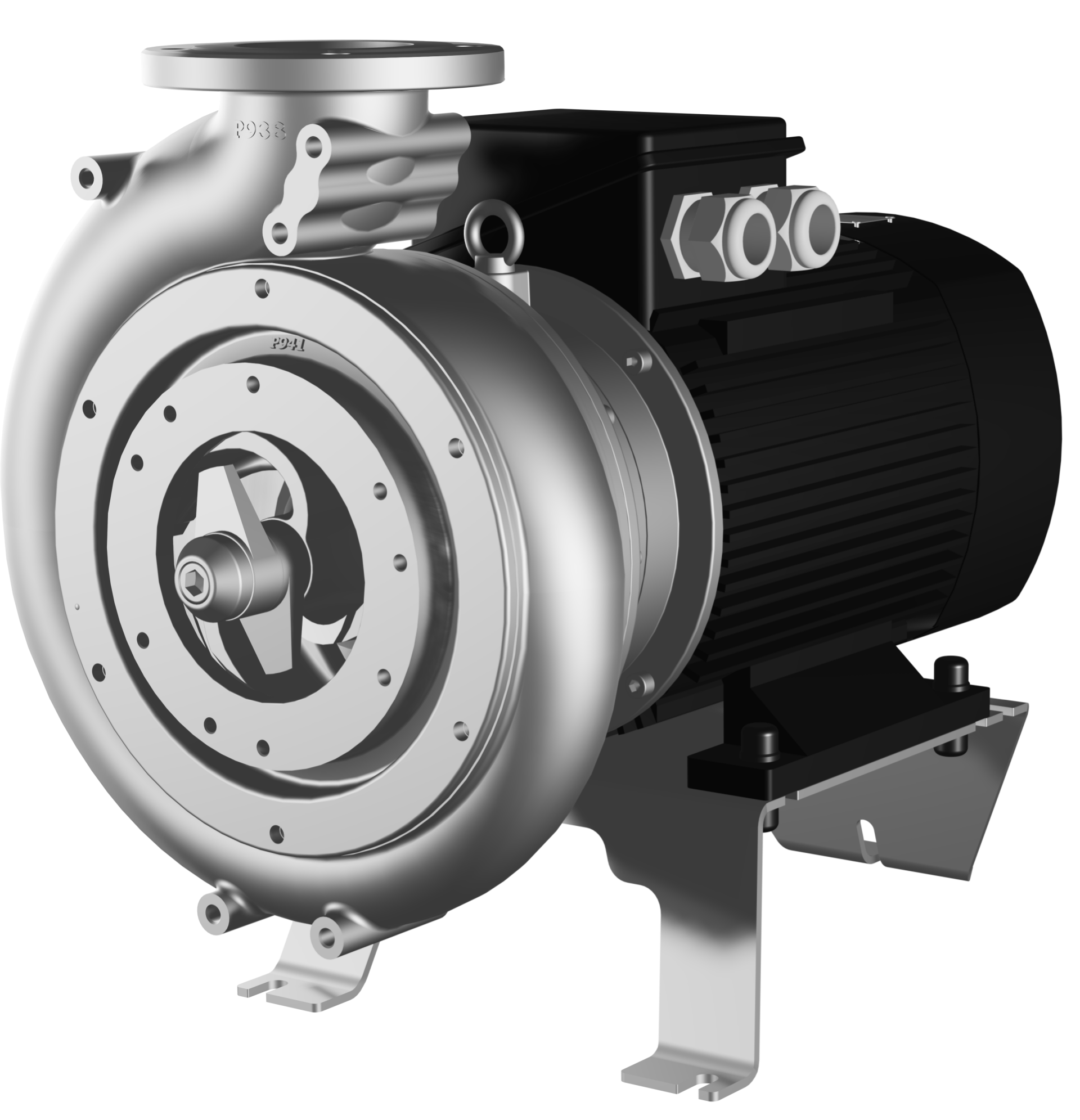

The model MPTK-I end-suction chopper pump is particularly suitable for biogas plants. This heavy-duty chopper pump is designed with an open impeller, which is the ideal design for pumping feedstocks with high dry matter content and high viscosity.

The pump’s unique chopping system, or knife system, proves extremely effective in situations, where large particles and contaminants often create problems for other types of pump.

The benefits of a chopper pump for biogas

Where the pumps stand out from other pumps is that the pumps both pump and chop in one function. This not only counteracts clogging and blockage, but it is also an advantage for the entire biogas process. Due to the reduced particle sizes, the biomass becomes easier to convert for the bacteria inside the reactor. The operating range of the pumps is up to 6 bar, which is why they can also replace most types of displacement pumps.