Anaerobic digester mixing

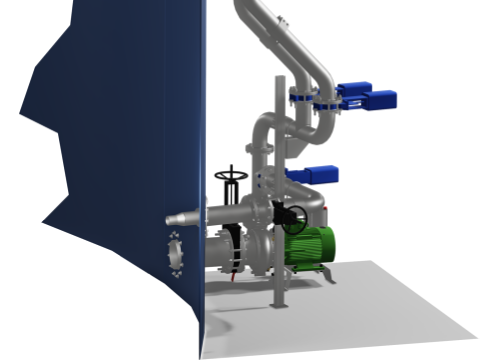

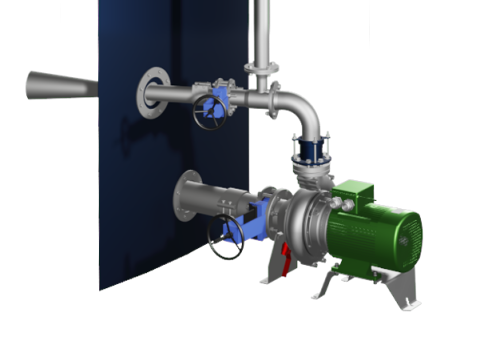

The Landia GasMix system offers the optimum mixing solution for anaerobic digesters in municipal wastewater treatment plants. The patent-pending GasMix utilizes both gas and sludge recirculation for mixing the digesters, ensuring effective VS destruction.

For Aerobic digesters consider our Pump mixing solution.

Related products

Get the most out of your anaerobic tank with Landia GasMix

The anaerobic digester is one of the most important components in a modern, energy-producing sewage treatment plant. In order to achieve the greatest possible biogas yield and the greatest possible sludge reduction, it is crucial to choose the right mixing system from the beginning. Landia offers, as the only supplier on the market, the unique GasMix mixing system, which utilizes the recycling of biogas and sludge to mix the contents of the digester.

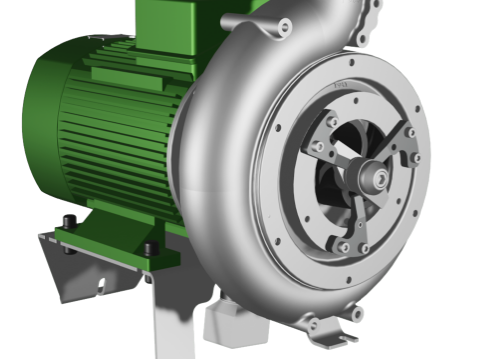

Landia GasMix has all components located outside the digester, which is an obvious advantage in terms of servicing the system. All service can be performed at the base of the digester, and should the system fail, the biogas process continues, as you do not have to open the tank for repair – unlike most other types of mixers for anaerobic digesters.

Landia GasMix for your anaerobic digester

In a collaboration with Aarhus University, Denmark, Landia GasMix has been shown to provide effective mixing compared with traditional technology. This effect becomes clearer the higher the dry matter content.

When the sludge passes through the GasMix ejector, it is subjected to a treatment in which the sludge particles are “split” apart – a feature that makes the tank contents easier to mix and reduces the risk of crusts.

Case studies - wastewater

A strong partner with extensive experience in biogas

You will not find anyone who has more experience with pumping and mixing solutions for biogas plants than Landia. We have been involved since the biogas industry’s infancy in Denmark, and today you will find Landia products in biogas plants worldwide.

The biogas industry is growing year by year and we are keeping pace.

When you contact Landia, you will speak with employees who know the industry, including some who have worked in biogas plants themselves.