From waste to biogas – “Waste-to-Energy”

Many different types of waste products can be extensively recycled in biogas plants. It requires the right pumps and mixers in the right materials – Landia can offer you a customized solution that suits your needs.

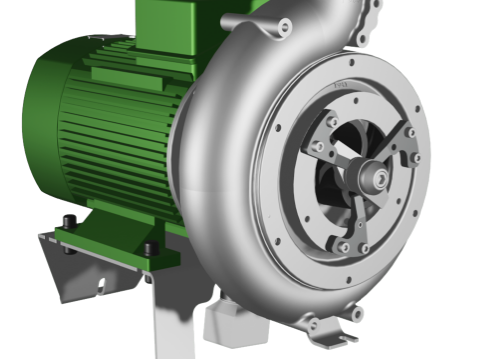

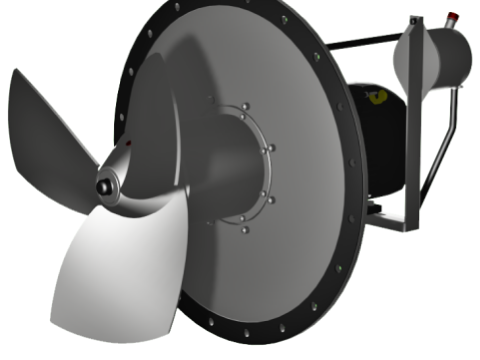

Related products

Food waste and household waste – we can handle that too!

Waste or by-products from households, restaurants and commercial kitchens are a resource in themselves and are widely used for biogas production. It places high demands on the mechanical components of the biogas plant.

Landia has a complete product line of stainless pumps and mixers that are targeted at waste-to-energy.

The products are adapted to the current task and corrosion, pH value, temperature and abrasive particles such as sand are considered.

Landia develops the best solution for your needs, whether they are mixers or pumps for pulp from food waste, biomass from source-sorted household waste, abattoir waste and waste from the food industry in general.

Advice on the right choice for your biogas plant

When you contact Landia, you will talk to employees who know the industry

– some even have a past in a biogas plant.

You get good advice and guidance from dedicated employees for whom satisfied customers are the be-all and end-all.

Case studies - biogas

A strong partner with extensive experience in biogas

You will not find anyone who has more experience with pumping and mixing solutions for biogas plants than Landia. We have been involved since the biogas industry’s infancy in Denmark, and today you will find Landia products in biogas plants worldwide.

The biogas industry is growing year by year and we are keeping pace.

When you contact Landia, you will speak with employees who know the industry, including some who have worked in biogas plants themselves.