GasMix Digester Mixing System for wastewater

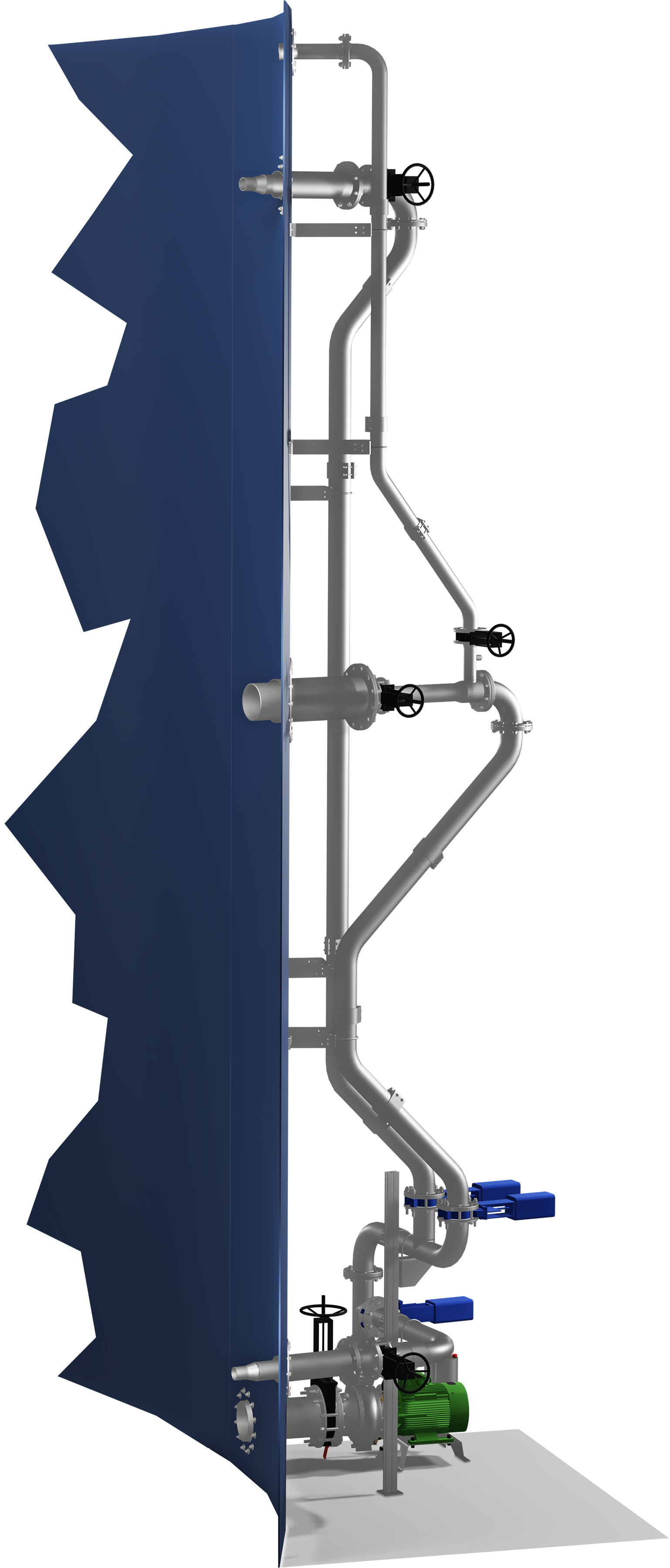

The Landia GasMix system offers a groundbreaking mixing solution for anaerobic digesters in Water Resource Recovery Facilities.The GasMix system has all its mechanical components located outside the tank, thereby allowing all service and maintenance to be completed without having to empty the tank or enter the sealed digester environment.

This provides obvious advantages in terms of safety, and there is also an economic benefit, as production can continue unhindered during any service work.

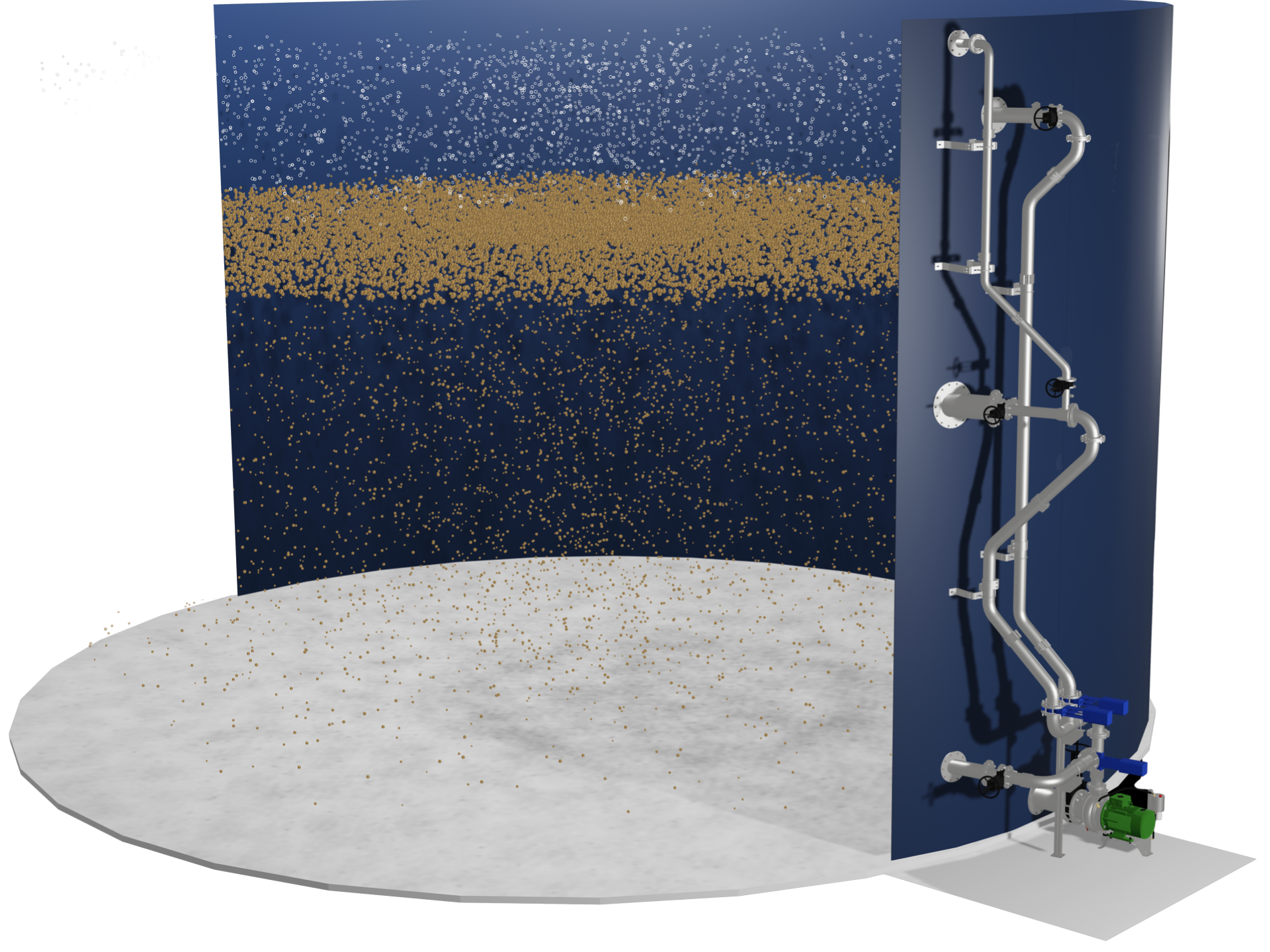

How Landia GasMix works for wastewater

The mixing with Landia GasMix works in such a way that a mixture of liquid and biogas is recycled in the tank. This keeps the tank mixed, and at the same time it contributes to a better biogas quality with higher biogas production.

It has been documented that the GasMix system leads to increased sludge reduction, and as a result you even achieve a higher biogas production.

Landia GasMix can be used with most tank types and at tank volumes up to approx. 350,000 ft³ and for sludge with DM up to 14%. The mixing effect can be documented with CFD simulation.

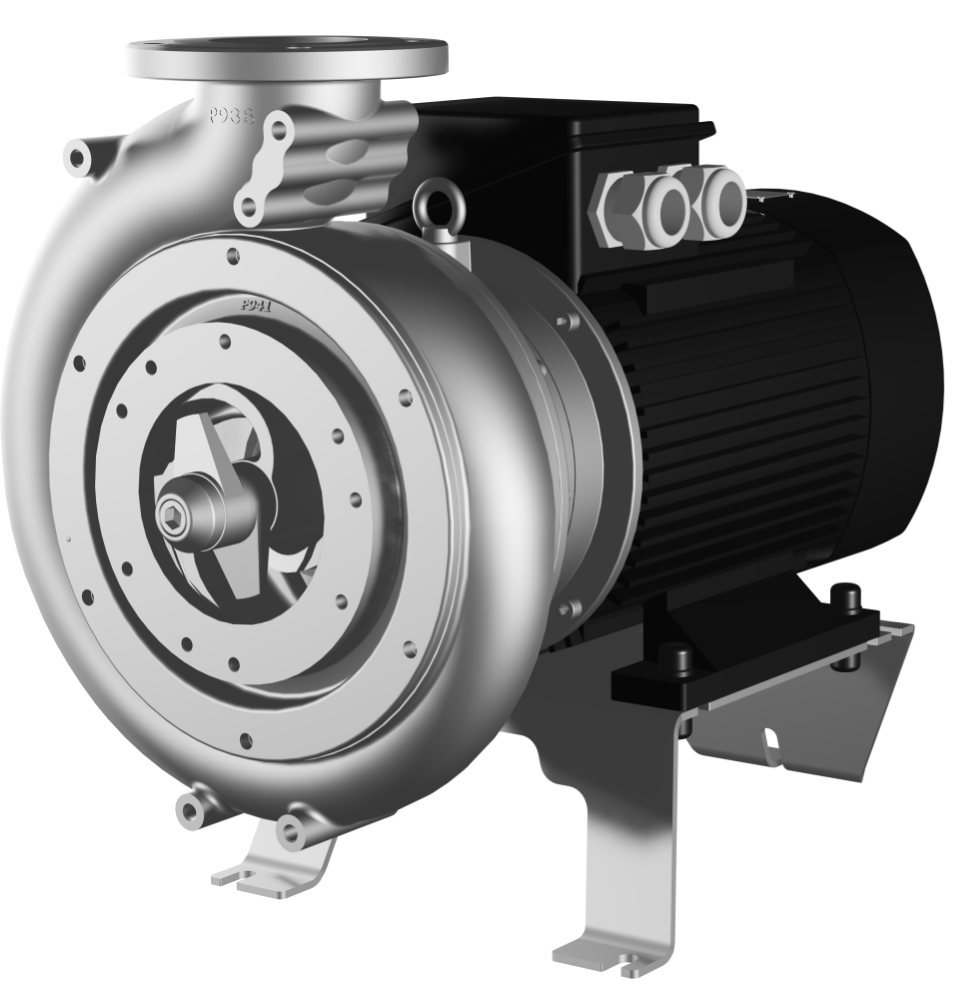

Chopper Pump MPTK-I

| Capacities | up to 475m3/h |

| Heads | up to 50m |

| Motor sizes | 15.0 - 37.0kW |

| Available with | Ex motor / IE3 motor |

Our solutions within wastewater

Mixing sludge

More than 40 years with solutions for mixing sludge in sewage treatment plants.

Case studies - Landia GasMix

A strong partner with extensive experience in biogas

You will not find anyone who has more experience with pumping and mixing solutions for biogas plants than Landia. We have been involved since the biogas industry’s infancy in Denmark, and today you will find Landia products in biogas plants worldwide.

The biogas industry is growing year by year and we are keeping pace.

When you contact Landia, you will speak with employees who know the industry, including some who have worked in biogas plants themselves.