Mixers for wastewater

Get the mixing that best suits your wastewater system with a mixer or flow generator from Landia.

We have solutions for large volumes of water, smaller tanks and for liquids with varying amounts of dry matter content.

The benefits of a submersible mixer for wastewater (low speed)

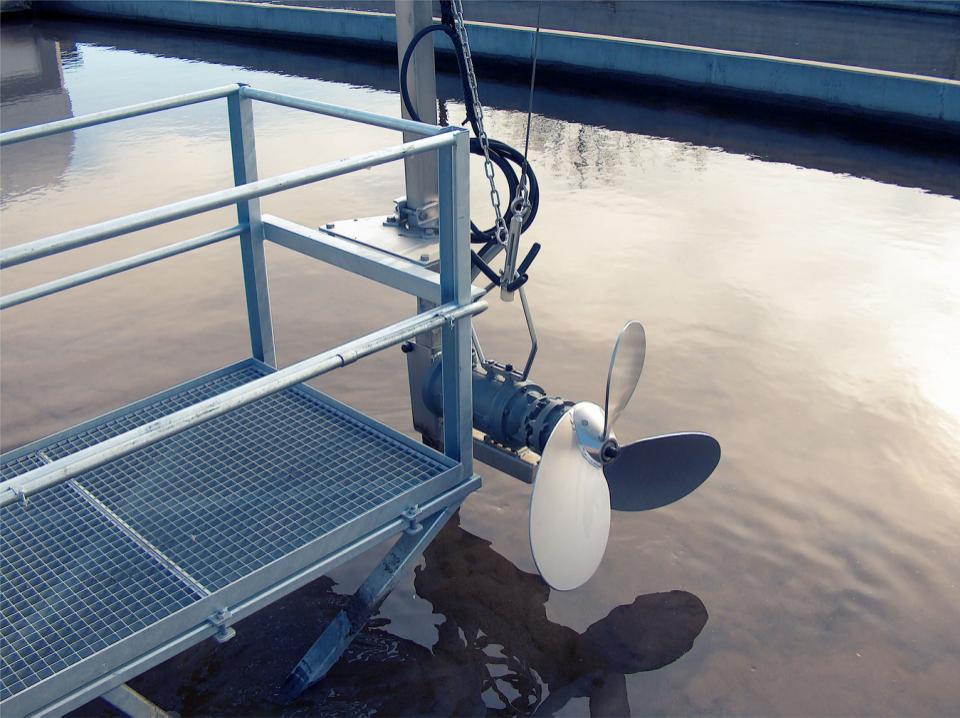

Landia POPL-I is a low-speed mixer or generator flowmaker. Its primary use is for mixing and creating flow in large volumes of water at an exceptionally low energy consumption.

With the adjustable propeller blades, the energy consumption can be adjusted by changing the angle of the propeller blades. it may be possible to achieve an energy consumption that is less than 0.0283 W/ft³.

The propeller blades on a POPL-I Flowmaker are made of stainless steel. Experience shows that the propeller blades last forever, and you therefore get a lifetime warranty on propeller blades on your POPL-I mixer.

If your wastewater is of an aggressive nature, POPL-I can even be supplied in acidproof stainless steel.