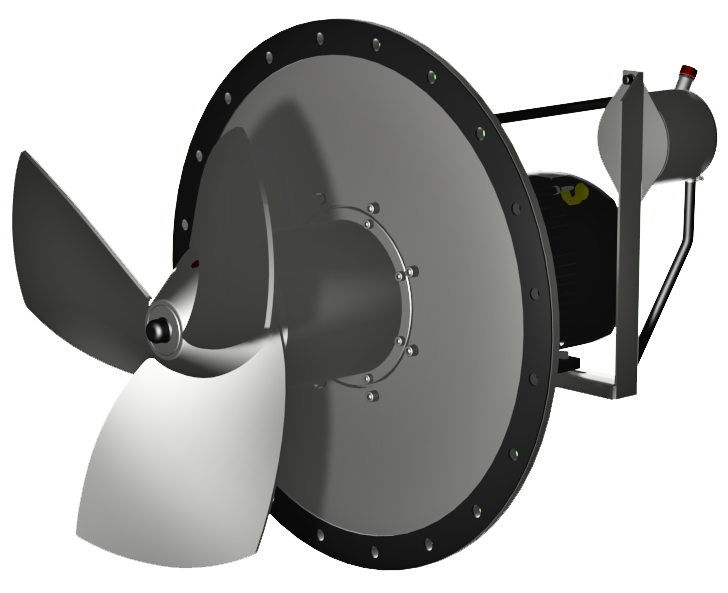

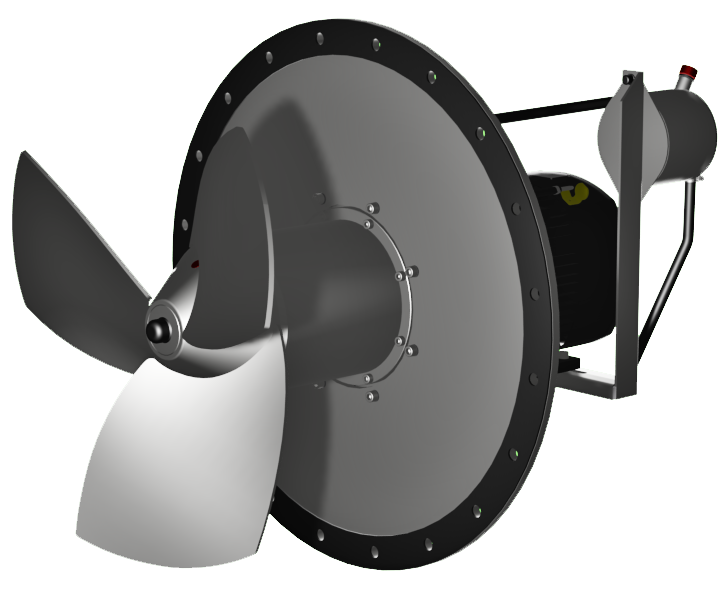

Side-entry mixers for industrial applications

Landia POPTR-I is a dry-installed mixer, which is typically used for liquids with a high dry matter content or liquids with a high temperature.

The benefits of the mixer’s mounting

A POPTR-I mixer is mounted through the side of the tank wall, thereby ensuring that regular lubrication and prescribed oil changes can be done from the outside. Thus, allowing the machine to continue its daily operation without needing to empty the tank or lift the mixer out.

The fan-cooled motor is completely shielded from the liquid, and it can even be replaced without emptying the tank.

POPTR-I is supplied as standard with all liquid-affected parts in stainless steel.

Landia POPTR-I can be installed in concrete, as well as steel tanks.