Landia GasMix for industrial purposes

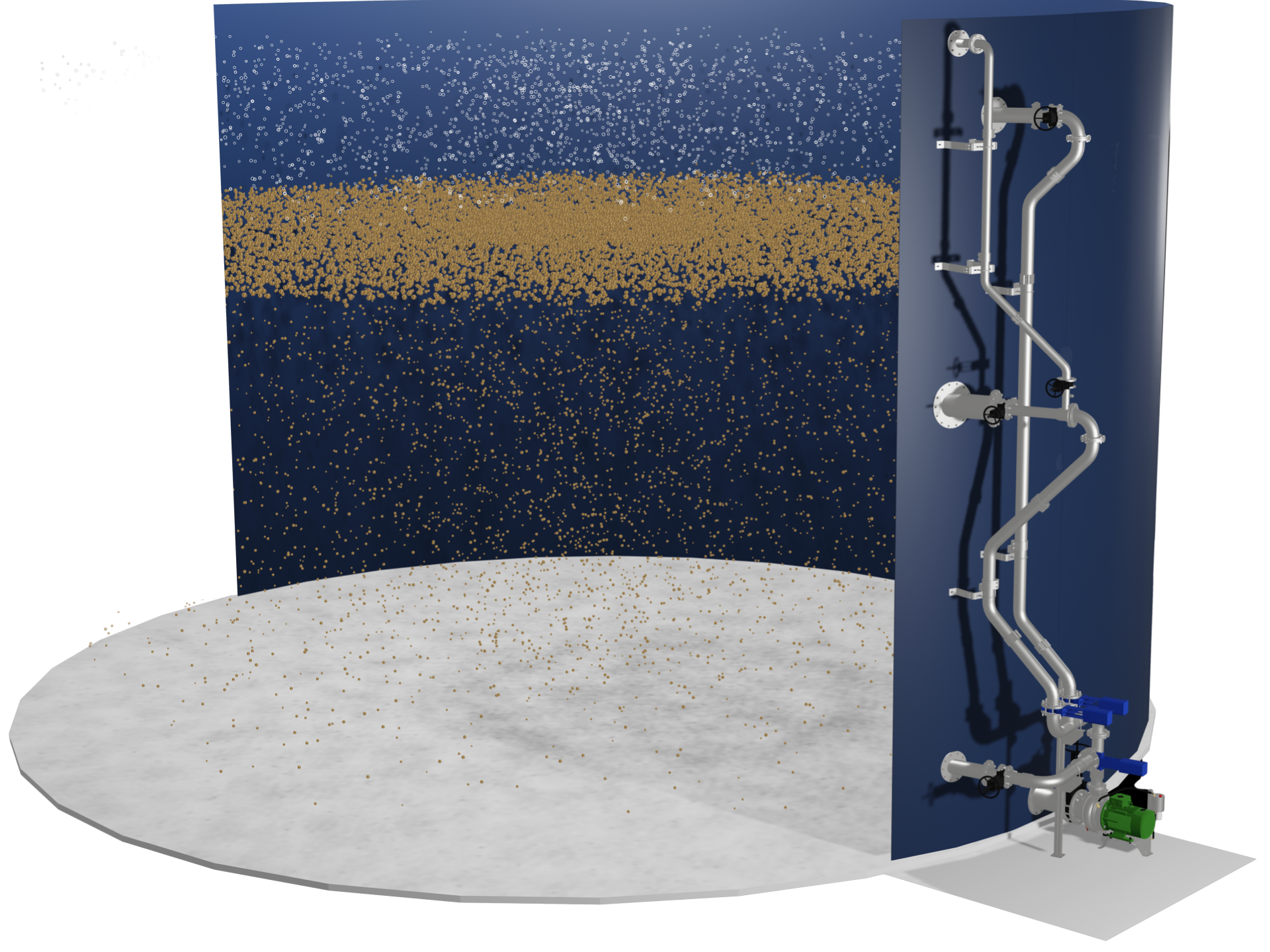

Landia GasMix is a mixing system that is suitable for all types of digestion tanks and reactor tanks.

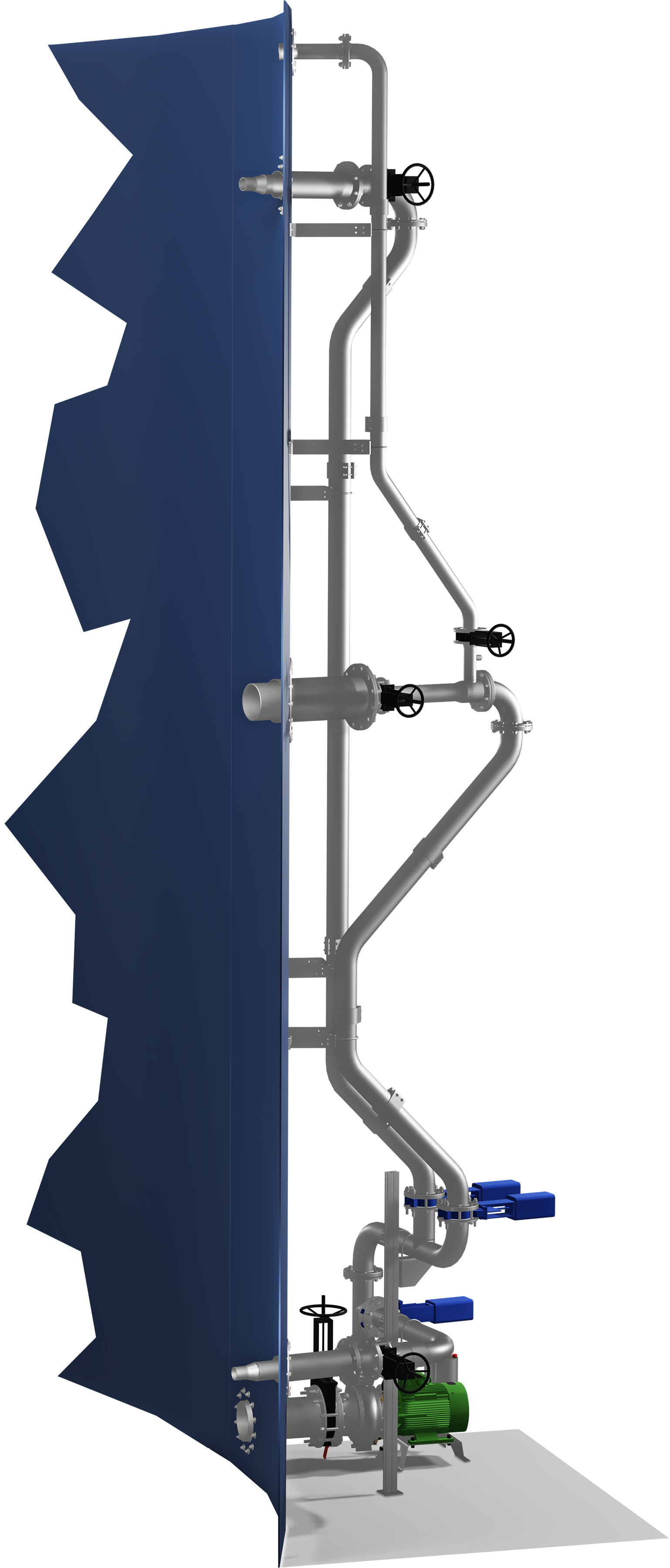

All mechanical components on GasMix are located outside the tank. Therefore, it is not necessary to open or empty the tank when performing service or repairs on the GasMix system. In addition to the safety aspects, the system also offers financial benefits as biogas production can continue while service is performed.

The benefits of GasMix for industrial use

The mixing with Landia GasMix works by recycling a mixture of liquid and biogas in the tank. This not only keeps the tank mixed, but it also contributes to a better biogas quality with hence higher biogas production.

Landia GasMix can be used with most tank types, at tank volumes up to approx. 353,147 ft3 and for sludge with DM up to 14%.

Dry-installed chopper pump MPTK-GI

Dry-installed chopper pump MPTKR-GI

Our industrial solutions

Food industry wastewater

Landia produces and supplies solutions for pumping, mixing and aerating all types of wastewater from the food industry.

Residual products, food production

Landia offers a wide range of pump and mixing solutions for handling residual products from abattoirs, the fishing industry, wastewater from dairies, vegetable production and much more.

Waste-to-Energy

Landia’s pumps are designed to meet all challenges with biomass, and they are tailored to the waste-to-energy segment and the green transition.

Case studies - Landia GasMix

A strong partner with extensive experience in biogas

You will not find anyone who has more experience with pumping and mixing solutions for biogas plants than Landia. We have been involved since the biogas industry’s infancy in Denmark, and today you will find Landia products in biogas plants worldwide.

The biogas industry is growing year by year and we are keeping pace.

When you contact Landia, you will speak with employees who know the industry, including some who have worked in biogas plants themselves.