Industrial aerators

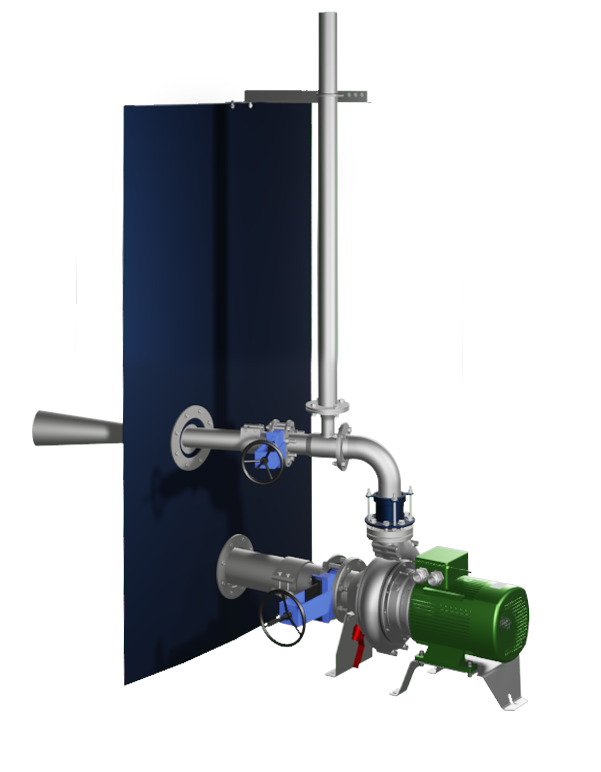

Landia’s aerators can be installed in most types of tanks. They can be supplied in a submersible version where the entire aerator is lowered into the tank or for mounting through the side of the tank - dry-installed.

AirJet for industrial aeration

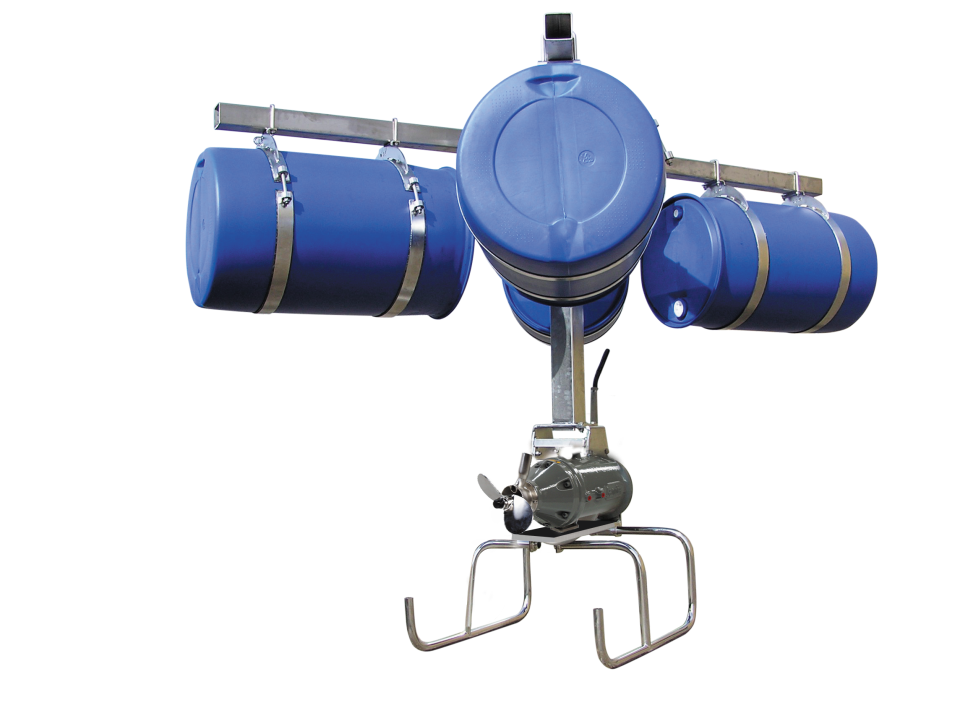

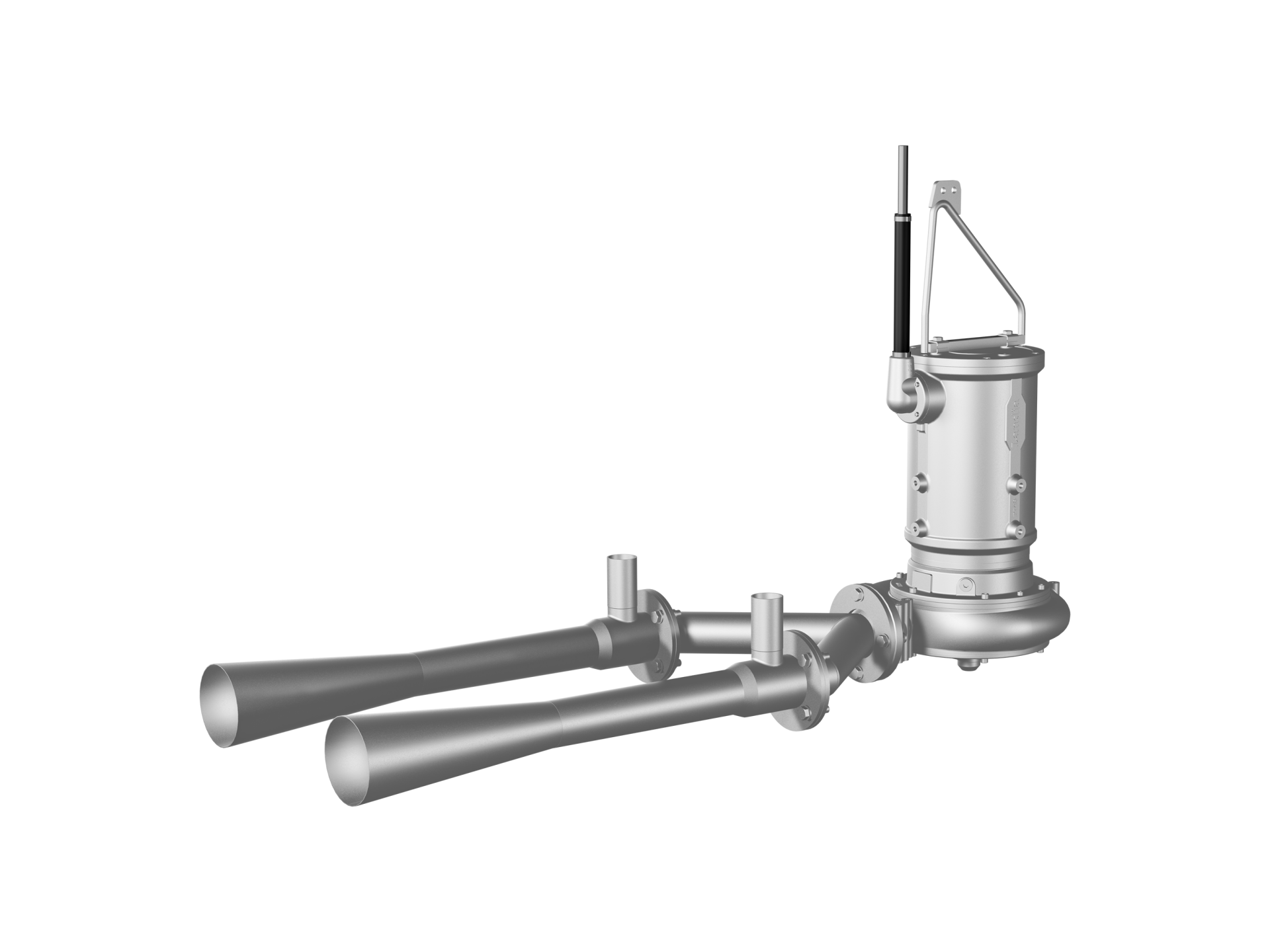

Landia AirJet is an ejector aerator consisting of a Landia chopper pump and an ejector system.

AirJet is a simple and uncomplicated aeration system that can be installed in most tank types, in some cases without the tank having to be emptied and is therefore extremely easy to work with in the industry.

Applications for Landia AirJet

- Aeration of wastewater or sludge

- Combined mixing and aeration

- Elimination of troublesome odours from wastewater, as the wastewater is kept fresh

- Additional aeration at peak loads

- Cleaning/flushing of equalization tanks

Landia AirJet sucks air down to 22.97 to 26.25 ft water depth. The aerator requires no maintenance, as only the pump needs to be serviced.

The ejector aerator is also available in stainless steel.