Chopper pumps for industry

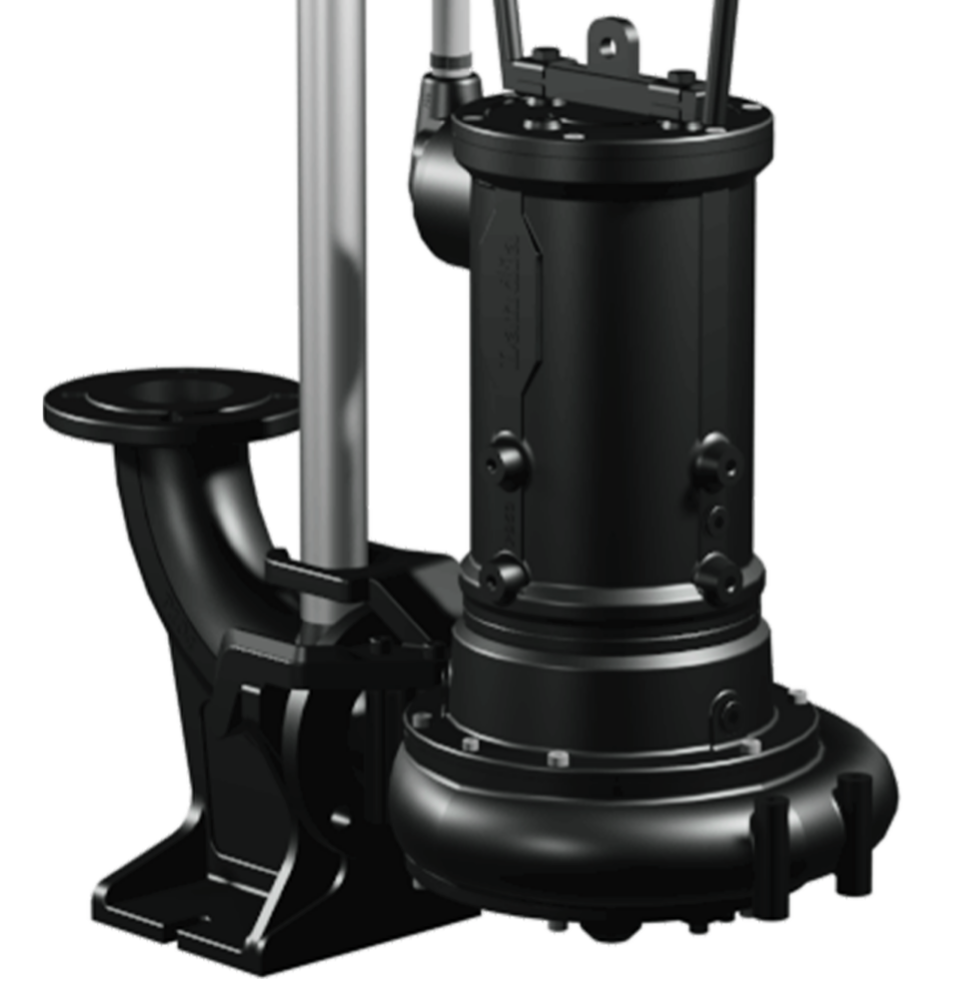

The DG-I pump is a series of submersible pumps, which are designed to pump heavily contaminated liquids, as well as liquids with a high dry matter content.

All DG-I pumps are chopper pumps fitted with a knife system at the pump inlet. This ensures that the operation runs smoothly under conditions where many other pumps will have problems with clogging.

The benefits of the DG-I submersible pump

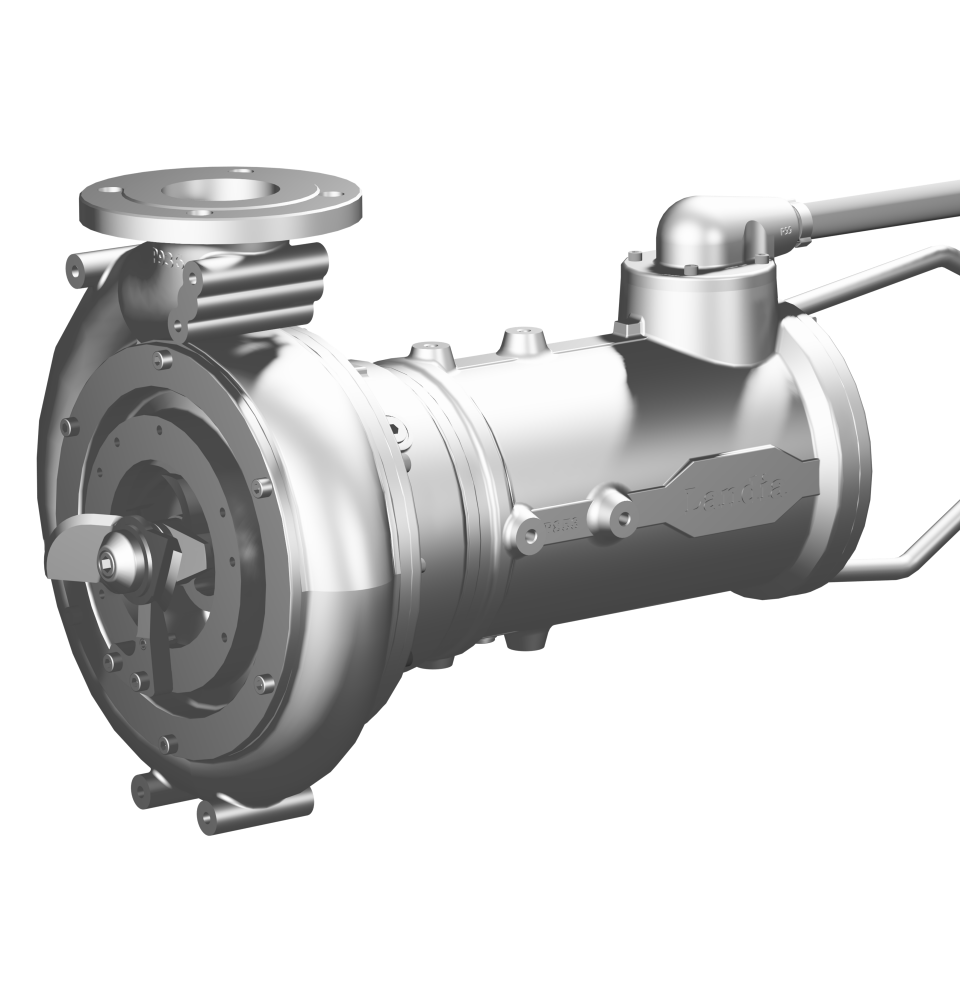

These pumps are developed by Landia for pumping liquids that have a high viscosity. They are therefore particularly suitable for pumping sludge and grease, as well as food waste, pulp and the like. The pumps have an operating range of up to 6 bar. Therefore, they can replace most types of displacement pumps.

In the presence of abrasive particles, such as sand, Landia has even developed several special materials that will extend the service life of the pumps considerably. This means lower long-term operating costs.

Most of the DG-I range can be supplied in stainless steel, which is suitable for pumping aggressive liquids with low or high pH. The areas of application are innumerable within wastewater, biogas plants, food industry, waste-to-energy, etc.