MBBR mixers for wastewater

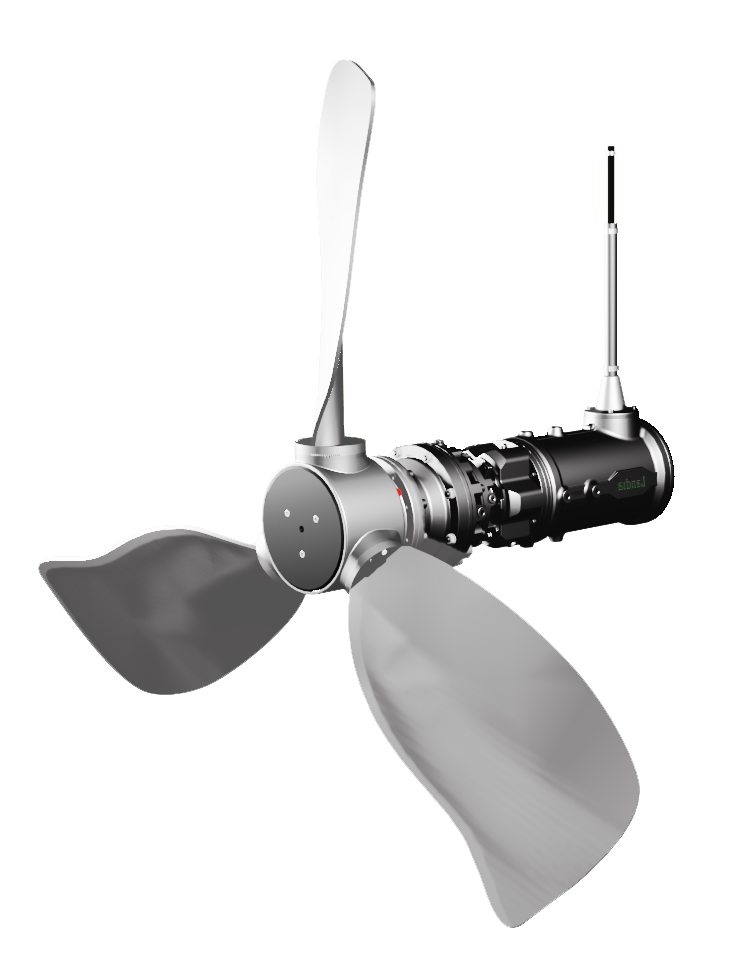

Landia BioMover is specially developed for gentle mixing of the liquid plastic carrier elements (biomedia) in MBBR tanks.

The benefits of a BioMover MBBR mixer

The liquid biomedia used in the MBBR processes in modern sewage treatment plants is usually made from HDPE. They are constructed in such a way that they have an exceptionally large, internal surface area. Here, the bacteria can grow without being knocked off or otherwise destroyed when they rotate and hit each other.

The slowly rotating, stainless steel propeller ensures a gentle and energy-efficient mixing of the biomedia. The gentle mixing prevents wear. Landia Biomover ensures that the entire contents of the tank are kept in motion and that biomedia does not clog the grate or sediment on the bottom of the tank.